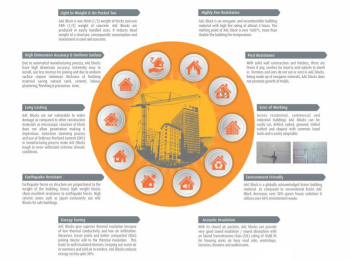

- Autoclaved Aerated Concrete (AAC) blocks are superior quality building material formed by a chemical reaction between finely divided calcareous and siliceous material resulting in creating millions of tiny air cells giving it a strong cellular structure.

- AAC Blocks are further strengthened by high pressure curing in temperature controlled autoclaves resulting in strength/density ratio better than conventional brick.

- Invented in 1923 by the Swedish architect and inventor Dr. Johan Axel Eriksson and has been around for over 90 years with being extensively used in Europe, Japan & China.

- With emerging requirements & increased awareness, eco-friendly AAC building are growing exponentially in india .

- AAC Block is one third (1/3) weight of bricks and one fifth (1/5) weight of concrete. AAC Blocks are produced in easily handled sizes. It reduces dead weight of a structure, consequently consumption and investment in steel and concrete.

- Due to automated manufacturing process, AAC blocks have high dimension accuracy. It is extremely easy to install, use less mortars for joining and due to uniform surface require minimum thickness of finishing material saving natural sand, cement, labour, plastering/finishing & precocious time.

- Earthquake forces on structure are proportional to the weight of the building, hence light weight blocks show excellent resistance to earthquake forces. High seismic zones such as Japan exclusively use AAC Blocks for safe buildings.